one stick drive skid steer mission planner move the throttle stick on your transmitter to maximum. add power to the ESC. At this stage . Doorway Digger-manufacture,factory,supplier from China. (Total 24 Products for Doorway Digger) Doorway Digger Rippa 0.8 Ton. The body width is only 93 cm. Contact Now. Doorway Digger 12000 lb Excavator.

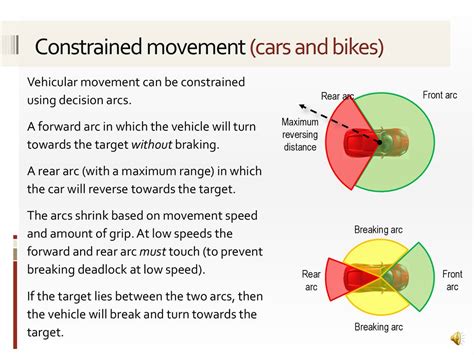

0 · Steering Input Type and Reversing Behaviour

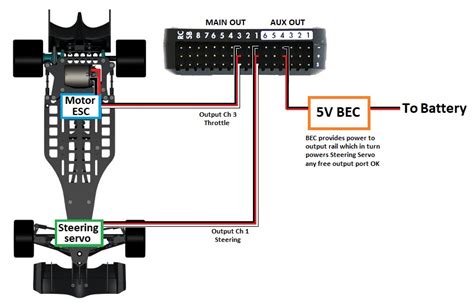

1 · Motor and Servo Connections — Rover

2 · Motor and Servo Configuration — Rover documentation

3 · How to Setup a Skid Steering on Mission Planner with Herelink

Rent a 4.5 - 5 Ton Mini Excavator Rental from one of our over 1,200 THD rental locations. Call your local store for same day pickup availability.

Learn how to set up and test the steering and throttle methods, motor driver types, ESC .move the throttle stick on your transmitter to maximum. add power to the ESC. At this stage . Suppose I only want to use one joystick for the rover’s skid steering (throttle left .

This Two Paddle Input method can be enabled by setting PILOT_STEER_TYPE to “1”. Once .Learn how to wire and configure your rover's motor and servo connections depending on the steering and throttle method. Find the parameters values for .Learn how to set up and test the steering and throttle methods, motor driver types, ESC configuration, and minimum throttle for rover vehicles. Use the Mission Planner to check the motor direction, dead zone, and speed scaling. Suppose I only want to use one joystick for the rover’s skid steering (throttle left and throttle right). How can I configure this one? These are the parameters that I have set in Mission Planner.

This Two Paddle Input method can be enabled by setting PILOT_STEER_TYPE to “1”. Once enabled, raising RC input 1 channel high is like controlling the left motor of a skid-steer vehicle so the vehicle will turn right.

Steering Input Type and Reversing Behaviour

Learn how to wire and configure your rover's motor and servo connections depending on the steering and throttle method. Find the parameters values for separate steering, skid steering, omni vehicles and wheel encoders. I can now see the servo outputs on mission planner behaving as I think they should ie both servo1 and servo3 move together when I move the transmitter throttle stick up and down. And servo1 and servo3 move in opposite directions when I . If your rover has separate motors for left and right, then the differential speed is, by definition, how it will be driven. This is called skid-steering. You tell Ardurover that this is the type of physical setup you have by setting the RC channel functions for your left and right servos to ThrottleLeft (73) and ThrottleRight(74). -200lb custom built steel frame rover. It resembles a very small UPS truck. -Casters up front, 2 independent 750w rear motors. -2x60 Sabertooth controller. -Pixhawk. -Futaba RxTx system. -915mz telemetry. -5.8ghz video transmission. As for what we have tried: -Setup as a rover in Mission Planner.

It should be possible to test that the motors work using the Mission Planner’s motor test screen. “Test Motor C” should make the left motor turn forward, “Test Motor D” should make the right motor turn forward.

Motor and Servo Connections — Rover

The problem is with the ArduPilot Rover Boat model which only provides an either/or choice of differential skid steering, or fairly conventional speed on 1 channel, direction on 2nd channel control models.Mission Planning. This section contains articles about creating missions that will run when the vehicle switched to AUTO mode. Note. The instructions focus on the Mission Planner but the main concepts apply to other Ground Control Stations as well. Recording Waypoints for a Mission. Planning a Mission with Waypoints and Events. Mission Command List

Learn how to set up and test the steering and throttle methods, motor driver types, ESC configuration, and minimum throttle for rover vehicles. Use the Mission Planner to check the motor direction, dead zone, and speed scaling.

Suppose I only want to use one joystick for the rover’s skid steering (throttle left and throttle right). How can I configure this one? These are the parameters that I have set in Mission Planner.This Two Paddle Input method can be enabled by setting PILOT_STEER_TYPE to “1”. Once enabled, raising RC input 1 channel high is like controlling the left motor of a skid-steer vehicle so the vehicle will turn right.

Learn how to wire and configure your rover's motor and servo connections depending on the steering and throttle method. Find the parameters values for separate steering, skid steering, omni vehicles and wheel encoders. I can now see the servo outputs on mission planner behaving as I think they should ie both servo1 and servo3 move together when I move the transmitter throttle stick up and down. And servo1 and servo3 move in opposite directions when I . If your rover has separate motors for left and right, then the differential speed is, by definition, how it will be driven. This is called skid-steering. You tell Ardurover that this is the type of physical setup you have by setting the RC channel functions for your left and right servos to ThrottleLeft (73) and ThrottleRight(74).

2012 john deere 17d mini excavator

-200lb custom built steel frame rover. It resembles a very small UPS truck. -Casters up front, 2 independent 750w rear motors. -2x60 Sabertooth controller. -Pixhawk. -Futaba RxTx system. -915mz telemetry. -5.8ghz video transmission. As for what we have tried: -Setup as a rover in Mission Planner. It should be possible to test that the motors work using the Mission Planner’s motor test screen. “Test Motor C” should make the left motor turn forward, “Test Motor D” should make the right motor turn forward.

The problem is with the ArduPilot Rover Boat model which only provides an either/or choice of differential skid steering, or fairly conventional speed on 1 channel, direction on 2nd channel control models.

2013 bobcat e35 mini excavator 33 hp

Motor and Servo Configuration — Rover documentation

Find 57 used Jcb mini excavators for sale near you. Browse the most popular brands and models at the best prices on Machinery Pete.

one stick drive skid steer mission planner|Motor and Servo Configuration — Rover documentation